About Us

You are here: Home About Us

Our Leadership Team

We, the employees of King Nut, pledge to ourselves, co-workers, customers and company that we will do all that we can to maintain the highest level of quality in every aspect of our job. This will be done to the best of our abilities—making every day a new day to achieve higher quality standards for the products that we make at King Nut.

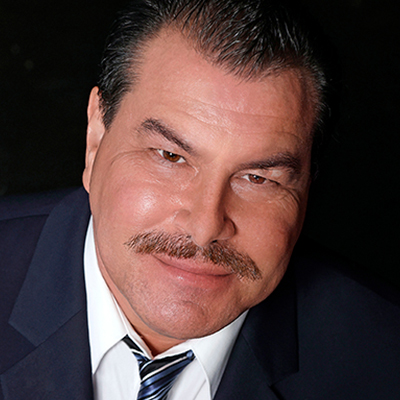

Michael Kanan

Mr. Kanan has been chairman since he bought King Nut Company in 1989. He also was President and Chief Executive Officer through 2003. He has been a food industry executive his entire professional career.

Prior to King Nut he was an executive officer at Ever Fresh Juice, Inc. and John Labatt, Ltd. Born in Detroit, Michigan, Mr. Kanan has a BS in Accounting from the University of Detroit. In his role as chairman, he mainly is involved in the company’s finance and acquisition activities. In his past role as President, he was the leader in the acquisition of both King Nut and Peterson Nut. Mr. Kanan has three grown children with his wife Betty and they reside in Chagrin Falls, Ohio and Marco Island, Florida.

Martin Kanan

Mr. Kanan has been President and Chief Executive Officer since October 2003. Mr. Kanan joined King Nut in 1991 as its National Sales Manager and has also been Vice President of Sales and Marketing.

In 2000 he became Executive Vice President and Chief Operating Officer. Mr. Kanan was instrumental in developing King Nut as the nation’s leader in supplying the airline industry with snacks. Prior to joining King Nut, Mr. Kanan was in sales management for Blissfield Manufacturing Company and also Shelby Enterprises—both are Michigan automotive and off-road OEM suppliers. Born in Detroit, Michigan, Mr. Kanan has a BA in Communications from Michigan State University. In his current role as President and Chief Executive Officer, Mr. Kanan oversees and leads the company’s complete operations. Mr. Kanan is married and resides in Moreland Hills, Ohio.

Matthew R. Kanan

Mr. Kanan has been Executive Vice President in charge of Sales and Marketing since 2003. Mr. Kanan joined King Nut in 1991 as a Regional Manager of Sales and Marketing.

He has also been the National Sales Manager and Director of Sales and Marketing. In his current role, Matt oversees the company’s complete sales force and is responsible for directing the company’s marketing initiatives, brand imaging, advertising, social media and public relations. He is also second in charge, assisting the President in running the company. Born in Detroit, Michigan, Matt has a BBA in Marketing from Western Michigan University.

Joseph A. Valenza

Mr. Valenza has been Senior Vice President and Chief Financial Officer since 2006. Before that he was Vice President and Corporate Controller.

Mr. Valenza joined King Nut in 1993 in customer service. Since then, Joe has held several positions in accounting and purchasing. He also was the assistant controller. As CFO, Joe oversees the company’s Financial and Administrative areas and helps operate and steer the company for its long term goals. All administration, finance, accounting, Treasury, purchasing, human resources, information technology and customer service ultimately report to Joe. Born in Warren, Michigan, Joe has a BS in Accounting from Western Michigan University, and has passed the CPA exam. Mr. Valenza resides in Lyndhurst, Ohio with his wife Karen and their two daughters.

Paul Storsin

Paul Storsin is our Vice President of Quality Assurance and Food Safety. Prior to this, Paul worked at Aladdin’s Baking Company as their Director of Quality and Food Safety since 2019 and also with Orlando Baking Company as their Director of Quality and Food Safety since 2012. Previously, he held quality management positions at Case Farms as well as Park Poultry.

Paul is responsible for creating and communicating an overall vision for quality and food safety within our company, setting goals and recommending organizational changes to achieve these metrics. Also, to communicate the company’s quality system to customers and to promote consensus, food safety and quality throughout the company to achieve world class goals. Mr. Storsin is the senior leader in our Quality Group and is responsible for managing and training his team members. He is responsible for all areas of quality assurance and HACCP programs, food safety and defense, research and development, nutritional programs, policies and procedures programs and sanitation.

Born in Canton, Ohio, Paul has a business management degree from Stark State College and extensive training in HACCP, BRC Global Standard for Food Safety, Internal Auditing and Laboratory Methods in Food Biology. He currently resides in Canton, Ohio with his wife Dodie. He has one son and two granddaughters.

Michael Smith

Mr. Smith is our Vice President of Manufacturing and Plant operations. Mike joined King Nut as a machine operator while in college in 2001.

He swiftly moved through the company ranks in many manufacturing, quality and management roles. His last appointment was as our managing Director of Manufacturing and Plant Operations and before that as plant manager for our plant #2. Mike has many years’ experience in SQF food safety training and in lean manufacturing. In this role Vice President, he leads our entire manufacturing operation which includes production, engineering, distribution, maintenance & facilities and all the personnel responsible for making and delivering our high-quality products. Born in Akron, Ohio, Mike has an education in Computer Science from Kent State University and lives in Shalersville, Ohio.

Justin Rosenberg

Mr. Rosenberg is our Vice President and Corporate Controller. He started with King Nut in November 2005 as our Accounting Manager. He moved up quickly to Assistant Controller, Controller then Director and Corporate Controller.

Justin has extensive experience in our company not only as lead accountant but also in customer service and in operations management. Justin leads our accounting, supply chain/ purchasing, inventory management and customer service groups; he continues to run the administrative side of our airline foodservice business as well. Born in Cuyahoga Falls, Ohio, Justin has as Bachelors of Science degree in Accounting from Kent State University and resides in Cuyahoga Falls, Ohio.

Welcome to King Nut

Ownership: 100% owned by Kanan Enterprises; Michael Kanan–Chairman; Martin Kanan –President and CEO and Matthew Kanan– Executive VP & Chief Marketing Officer

Employees: Approximately 375

Annual Sales/Revenues: Kanan Enterprises is a privately held company and does not disclose sales figures.

Production: 3 shifts; approximately 500 million annual packages produced.

Union: Plant Employees are all members of the Teamsters Union.

Headquarters: Solon, OH (suburb of Cleveland) Headquarters, manufacturing and main warehousing: 350,000 square feet spread throughout 3 buildings in Solon. Factory outlet store in Solon.

Products: Peanuts, Nuts, Dried Fruits, Trail Mixes, Snack Mixes, Pretzels.

Brands: King’s Delicious, Peterson’s, Summer Harvest Brands and Nature’s Basics plus numerous private label products.

Supplies for: Airlines, Supermarkets, Warehouse Clubs, Corporate Gifts, Convenience Stores, Ice Cream Toppings, Food Ingredients, Vending, Food Service, Private Label, Co-Packing and various other Retailers.

Airlines Customers: Delta, American, Southwest, JetBlue, Hawaiian, Korean, Spirit plus many other regional and international carriers.

King Nut’s Green Mission

At King Nut Companies maintaining the highest level of quality in every aspect of our job also includes striving for environmental sustainability. In April 2008 we began an aggressive reduction of energy usage as well as recycling as much of our waste as possible. We believe it is the duty and responsibility of ALL American corporations to help ease the strain on our environment. We hope our actions will serve as a model for other companies, both domestic and foreign, to take the initiative to reduce waste and energy consumption and leave a little bit smaller environmental footprint. Here’s what we’ve been able to do at the administrative & plant levels since the program’s inception:

- Reduced weight in our packaging by almost 38% in the past two years to save over 237,000 pounds annually of polyethylene plastic packaging.

- Replaced all factory and office lighting with energy efficient LED lighting.

- Recycling of all paper, plastic and aluminum products used by employees in the course of business.

- Eliminating the purchase of Styrofoam coffee cups and switching to recyclable utensils.

- Encouraging employees to only print when necessary and utilizing the two-sided print option.

- Recycle all corrugated materials as well as plastic film cores, tote liners & peanut super sacks.

- Power down all electrical devices and machines in all plants that are not in use. This greatly increases energy efficiency.

- Natures Basics line uses 40% post-consumer film.

Corrugated:

- 96% of all corrugated boxes are made with material supplied by certified fiber sourcing programs such as Sustainable Forestry Initiative ® (SFI), Forest Stewardship Council (FSC), and American Tree Farm System (ATFS). This is what makes corrugated fiberbased packaging the Sustainable Choice.

- Close to 90% of the all the corrugated converted by our supplier is 100% recycled, 93% post-consumer waste. Our primary corrugated sheet supplier uses mills that are state-ofthe-art and only manufacture 100% recycled linerboard and medium from OCC (old corrugated containers). Contrary to this, a small percentage of our corrugated products will contain less than 100% recycled fiber.

- Our corrugate supplier recovers approximately 95% of the post-industrial corrugated waste generated during the manufacturing process. This waste is baled and returned to paper mills for recycling. Corrugated is the single most recycled packaging material. 96 percent of corrugated produced in 2018 was recovered for recycling, and almost all of that material was recycled into new products.

All of our oil used for roasting is recyclable

Recycled Materials Breakdown:

Below is a breakdown of goods recycled from February 2020 through January 2021:

- Paper, plastic and aluminum – 3,300 lbs.

- PET bottles – 10,000 Lbs.

- Film cores – 24,500 lbs.

- Super sacks – 21,250 lbs.

- Corrugated materials – 950,000 lbs.

- Miscellaneous – 250 lbs.

- Total = 1,006,000 lbs.

Earth Day

King Nut Companies annually celebrates Earth Day where employees plant trees and other plants. Several employees also volunteer to clean up trash and waste along our properties here in Ohio.

Future Projects

These are simply a few actions we take to help improve our community and use less of the earth’s precious resources. King Nut Companies will continually search for ways to improve source reduction and increase energy efficiency that will enhance our environmental sustainability.

Rev. January 2021